The first recorded use of a wooden pencil dates back to the 16th century when graphite was discovered in England. Initially, graphite was used to mark sheep and later used for writing. However, graphite was very soft and brittle, which made it difficult to use. In 1795, a French artist named Nicholas-Jacques Conte discovered that mixing graphite with clay made it more durable and easier to use.

Step 1: Wood Selection

The first step in making a wooden pencil is selecting the appropriate wood. Pencil manufacturers usually select high-quality cedarwood from the Incense Cedar trees. Cedarwood is preferred because it's lightweight, doesn't splinter when sharpened, and has an even texture.

Step 2: Cutting Wood Into Pencil Slats

Once the cedarwood is properly sourced, it is cut into long, thin slats that form the basis of the pencil body. A standard pencil is 7.5 inches long with a diameter of 0.25 inches. The slats are then sorted according to the quality of the wood.

Step 3: Wood Treatment And Drying

The slats are then dried in a kiln (high-pressure chambers with heat exchangers), ensuring that every slat softens and reaches the right moisture level of 1-3% measured by the moisture meter reading. This process is critical because the slats may bend, twist or warp if not dried and treated properly.

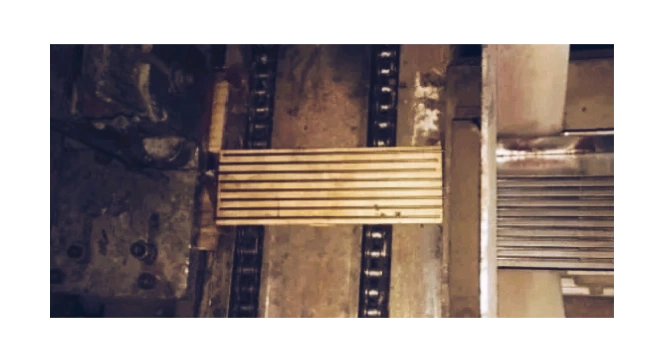

Step 4: Wood Slat Grooving

The next step is to make even slots on the wood slats with the Grooving Machine in order to place the lead graphite within.

Step 5: Lead Laying & Gluing Process

The grooved slats are placed in the automatic lead-laying machine. In this machine there are two strokes, the first stroke places the wood slate on the conveyor, and the other stroke adds specialized glue on the lead and covers it with another slat in order to make a sandwich. The specialized glue ensures a strong bond between the individual slats. The glue also penetrates the wood's grain, making it more durable.

Step 6: Shaping

After the glue has dried, the wooden block is then sent to the shaping machine. Here, the block is cut into slender pencil rods, which are then shaped into the familiar hexagonal shape using a high-speed cutter. Ashoka makes round, square, and triangular-shaped pencils.

Step 7: Lead Center Checking

It consists of two vision cameras with take the binary image of the pencil tip and calculate the off-centre of the lead. A certain tolerance is set in microns in which a slightly off-centre is accepted. Ashoka has the most advanced machine for checking the centre of the lead in a pencil.

Step 8: Coating & Lacquering

A lacquer coating is applied to the pencil to make it smooth and to protect the wood from moisture and other environmental factors. Ashoka uses 100% organic pigments that are non-toxic and safe for children.

Step 9: Dipping Process

The tip of the pencil is coloured by using the dipping process. The pencils are filled into a board of 150 pencils then these boards are levelled equally using a leveller for consistent colouring of the tip. Then these boards are dipped in a tray of a specified length, and 2-3 dips are made to each board according to the desired design.

Step 10: End-Cutting And Stamping

The end-cutting and stamping processes are the final steps in the making of a pencil. Here the end-cutting machine slices the lacquer marks from the edges of the pencil and makes a finish cut. Further, the pencils are branded and embossed with a heated metal die.

With the advent of technology, people have switched to digital tools for their writing needs. However, wooden pencils still have a special place in people's hearts. Wooden pencils are used for artistic work, sketches, and many other artistic endeavors. With increased environmental awareness, people are returning to wooden pencils as an eco-friendly alternative to plastic pens and mechanical pencils. In order to stay relevant, pencil manufacturers are using sustainable methods of sourcing wood, and eco-friendly methods of production.

In conclusion, the wooden pencil has come a long way since its inception in the 16th century. It has remained an integral part of people's lives despite the advent of digital writing tools. The wooden pencil continues to evolve and adapt to new challenges, and with sustainable sourcing and eco-friendly production methods, it will continue to be an essential tool for the years to come.

Stock up on all your school stationery supplies with Ashoka! We have the best selection of pencils and educational supplies to help you stay organized and focused during the school year. Get everything you need for the classroom and beyond with our unbeatable selection and unbeatable prices. Shop now and get the supplies you need for a successful year ahead!